The word piezo flourishes from the Greek word piezein which implies, to press or apply pressure. Today, this word is frequently used to indicate the piezoelectric impact a wonder has been put to use by the business since right around 100 years. They noticed that when mechanical pressure is applied to quartz gems, an electric charge is made in the gems. They named this the ‘piezo impact’. Basically expressed, piezoelectricity implies electricity that is gotten from pressure. During resulting tests, they recorded that the opposite is additionally evident, wherein applying an electric field to the quartz precious stone causes a versatile twisting gem. This was named the ‘backwards piezo impact’. It was subsequently found that the backwards piezoelectric impact could be utilized for delivering ultrasonic waves. A typical illustration of the utilization of the piezoelectric impact would be in a gas chimney lighter. As the client presses the catch, a spring-stacked mallet strikes an inbuilt piezoelectric material.

The pressing factor creates a charge that is adequate to deliver a sparkle that ignites the gas. Different models involve gas butane barbecues, cigarette lighters, and piezoceramic igniters in heaters. As piezoelectric materials, for example, gems and pottery are equipped for changing over electrical energy into mechanical energy, and the other way around, the field of nanopositioning stands to benefit from the utilization of piezoelectric actuators. Piezoelectric actuators are equipped for making exact movement coming about because of piezoelectric materials. Such accuracy positioning gadgets and frameworks have been in need for more than quite a few years now, and keep on progressing. In any case, it should be noted here that normally happening piezoelectric materials show a little piezoelectric impact. This raised the need to create polycrystalline ferroelectric pottery, for example, Barium Titanate and Lead Zirconate Titanate that show worked on piezoelectric properties.

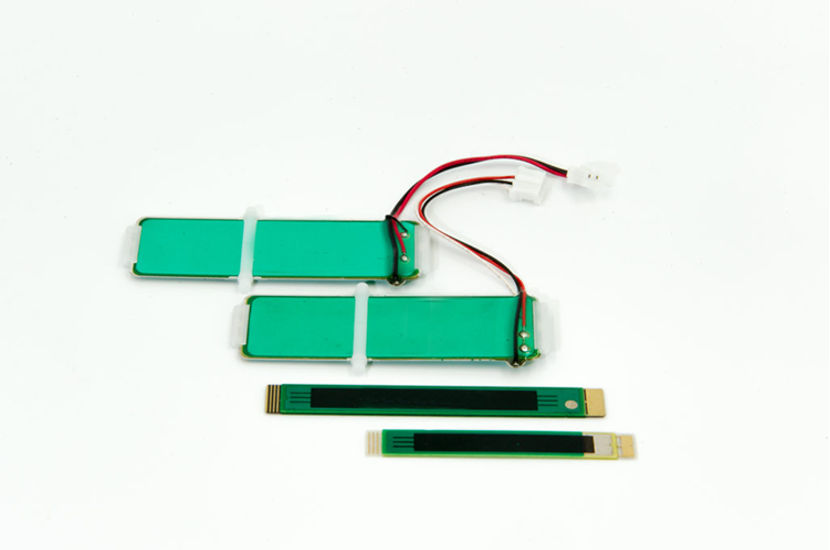

These materials are broadly utilized in nanopositioning applications including actuators or sensors. By stacking numerous layers of custom piezo material multi-facet actuator greater dislodging can be created at lower working voltage. The most recent multi-facet actuator plans are clay typified for excellent reliability and lifetime and have been tried for 100 billion cycles. They are equipped for accomplishing high-recurrence steps in the nanometer and sub-nanometer range. Since there are no mechanical parts adding to play and kickback, such actuators offer better repeatability. Piezo electric actuators require next to no power in static activity, in this way diminishing force supply prerequisites. They are without support, and not defenseless to wear. Flexure directing instruments that depend on the standards of piezoelectricity are additionally utilized in multi-pivot positioners and surprisingly in hexapod accuracy positioning frameworks. Piezoelectric hexapod stage positioners are distinctly better than customary water driven hexapods. Because of the great solidness and quick reaction, they can be worked as the two positioners and furthermore vibration dropping frameworks. Subsequently, hexapod accuracy positioning stages additionally benefit from the utilization of piezoelectricity standards.